Powers Scientific chambers are built to last: it’s not uncommon for us to receive requests for parts for equipment that is more than 15 years old. Some simple routine maintenance is an easy way to reduce electricity consumption, prevent costly breakdowns, and extend the life of a chamber. This is a short overview of the steps you can take to keep your refrigerator or incubator running like new for as long as possible.

Over time, the condenser fan, located near the compressor, draws in dust and debris from the surrounding air. This detritus accumulates on the fins of the condenser coil, reducing efficiency and increasing the workload on the compressor motor. Every 6 to 12 months, we recommend cleaning the condenser fan and coil. For chambers that have a bottom-mounted condensing unit, you’ll first need to remove the metal protective grille on the front of your chamber. The grille is attached with four #2 Phillips screws at the corners. Once the grille is removed, the coil and fan can be cleaned with a vacuum to remove dust buildup. A damp rag can also be used for cleaning, although a vacuum is ideal. If your chamber has a top-mounted condensing unit, simply use a ladder to safely climb up to clean the condenser coil.

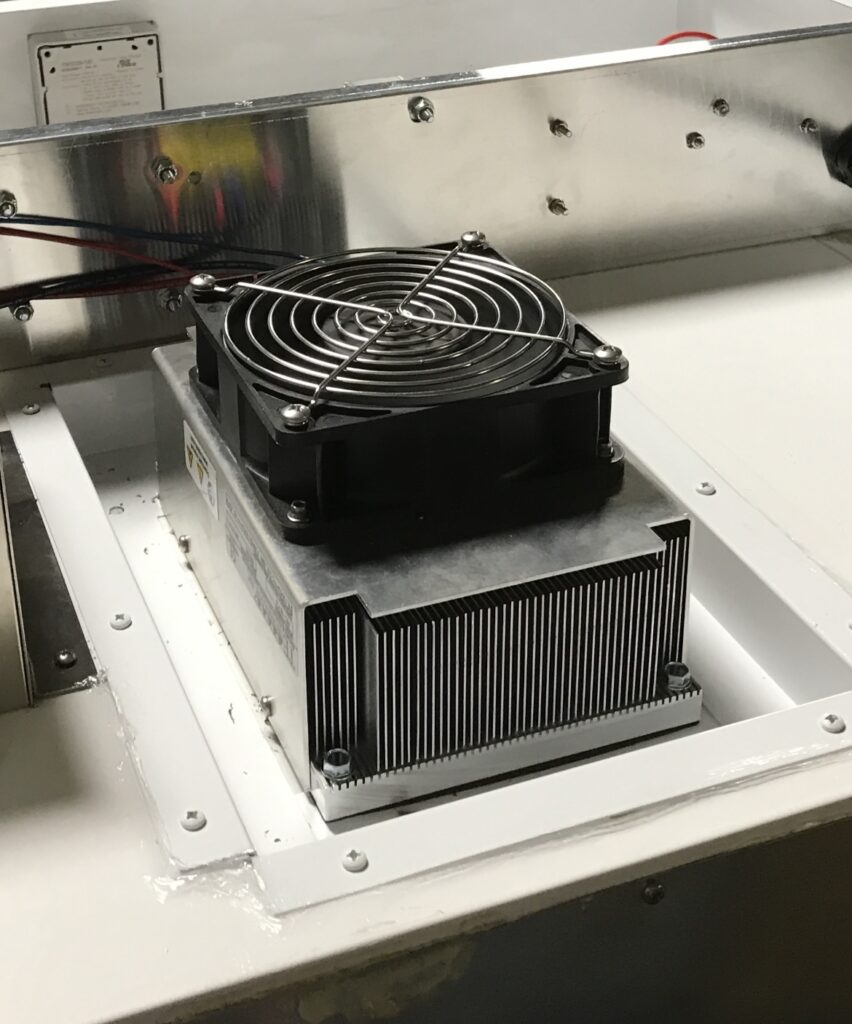

Our thermoelectric chambers, while they are extremely low maintenance, still need a similar type of cleaning to maintain maximum efficiency. The thermoelectric cooler is located on top of the chamber and includes a heat sink and fan that ventilates the hot side of the Peltier device. You can use a ladder to safely access the thermoelectric cooler, then use a vacuum with a small tip to remove the dust build up on the heat sink. This will restore the cooler back to the original cooling capacity and electrical usage. Just like with the condensing units, we recommend this cleaning to be done every 6 to 12 months.

We also recommend occasionally scrubbing the interior and exterior surfaces of our chambers. This will keep the chamber free of residues that can cause corrosion. This can be done on an as-needed basis, or on the same schedule as the condenser cleaning if you’d like to do everything in one go. For cleaning surfaces, we suggest using 70% isopropyl alcohol. In a well-ventilated area, gently scrub the chamber surfaces with a sponge. Do not clean the interior with any product containing bleach or ammonia as it will cause pinhole leaks in the copper refrigeration coils and/or corrode the aluminum fins surrounding them.

Of course, always remember to unplug the chamber before performing any maintenance activities.

For more information about our refrigerators or incubators, fill out our contact form or call us at (800) 998-0500.